ILT’s Micro-Center Septa is engineered to protect delicate SPME fibers during needle penetration while maintaining a secure seal for reliable analysis. It is compatible with automated and manual SPME workflows, supporting consistent, reproducible results.

ILT Micro-Center Septa for SPME: Reliable Needle Penetration Without Fiber Damage

Key Takeaways

- Micro-thin center liner reduces fiber damage and enables smooth needle entry.

- Thick outer wall supports a tight PTFE/Silicone seal and prevents septa fallout.

- This ILT product is compatible with SPME, static headspace, and dynamic headspace; made in the USA.

SPME workflows place unique demands on septa. Delicate fibers, repeated needle penetration, and automated sampling systems can lead to bent needles, fiber breakage, leaks, and inconsistent results. Standard headspace septa are often not designed to handle these conditions.

Purpose Built for SPME Applications

Unlike general purpose septa, ILT MicroCenter Septa is designed for solid phase microextraction, including automated SPME systems that use magnetic sample transport. The liner combines a standard outer thickness with a thinner, centered liner section to support repeated injections in demanding analytical environments.

This application specific design helps reduce downtime and extends the usable life of SPME fibers in routine and high throughput analysis.

Micro Thin Center for Easy Penetration

The defining feature of MicroCenter Septa is its micro thin center liner. The thinner center is easier to pierce than standard headspace liners, allowing needle penetration without breaking SPME fibers. Even small gauge needles pass through cleanly, reducing coring, deformation, and stress on automated systems.

This controlled penetration is critical for maintaining consistency and repeatability across runs.

Secure Seal With PTFE/Silicone Construction

While the center liner is optimized for penetration, the outer wall maintains a standard thickness. This ensures the septa seals tightly within the cap and prevents septa fall out during handling and analysis.

The PTFE/Silicone w/MicroCenter construction delivers the same sealability as standard headspace liners, allowing labs to maintain sample integrity without sacrificing penetrability.

Low Extractables for Clean Results

ILT MicroCenter Septa is manufactured from low extractable, low bleed silicone to help minimize background interference. Each liner is molded for dimensional conformity, supporting accurate, reproducible chromatography results across instruments and applications.

One Product for Multiple Applications

The MicroCenter Septa allows users to standardize on one cap and septa for multiple techniques, including:

- SPME analysis

- Static headspace

- Dynamic headspace

This versatility simplifies inventory management while maintaining consistent performance.

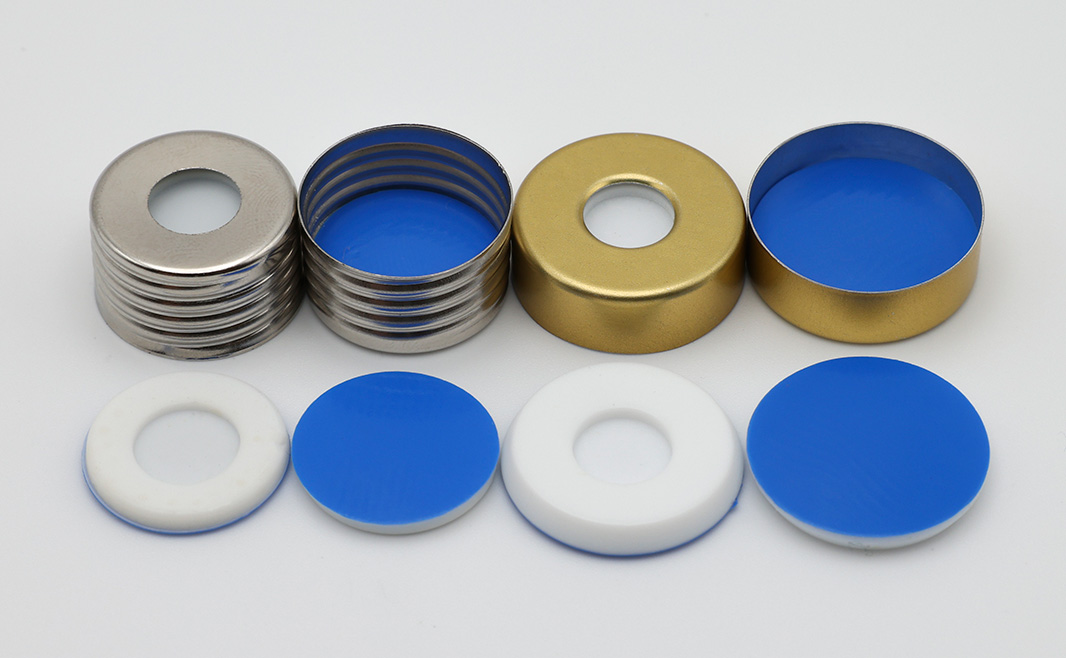

Available Configurations

ILT MicroCenter Septa is available in:

- 18mm screw caps

- 20mm crimp caps

- 18mm and 20mm septa only

Standard specifications include:

- Low bleed silicone/PTFE septa

- Outer liner thickness of 0.100″(2.5mm) and inner center thickness of 0.060″(1.5mm)

- 45 durometer

Designed and Manufactured by ILT

ILT is a trusted manufacturer of chromatography supplies with a focus on precision, durability, and application specific engineering. ILT MicroCenter Septa is designed and made in the USA to meet the demands of modern SPME analysis.

If you’re looking for the best SPME caps and liners that protect fibers and deliver consistent results, ILT MicroCenter Septa is a proven solution. Learn more about ILT’s made in the USA chromatography solutions today.