The Story of ILT

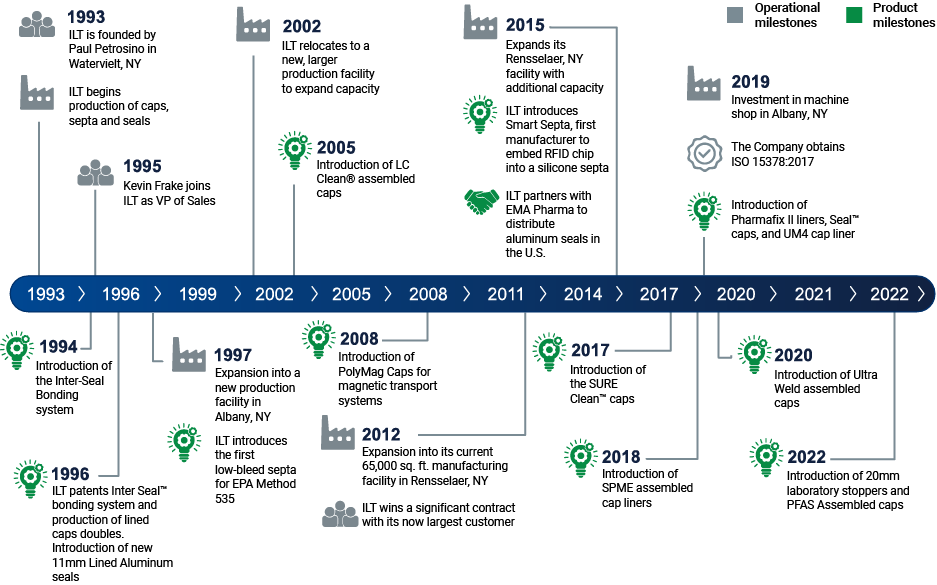

Paul Petrosino founded ILT in 1993 as a manufacturer of caps, septa, and seals used by analytical instrument OEMs in the chromatography market. An engineer with significant industry experience, Mr. Petrosino recognized OEMs needed chromatography consumables manufactured with a higher level of quality, reliability, and cleanliness. In 1994, Mr. Petrosino developed a chemically inert process to bond septa to plastic caps without using adhesives.

This revolutionary invention was an industry breakthrough that eliminated expensive and time-consuming hand assembly of caps, prevented costly liner fallout, and set the standard in the market. This innovation would become the basis for ILT’s flagship product, Inter-Seal® bonded caps. In 1995, Kevin Frake joined as VP of Sales of ILT bringing significant expertise and customer relationships from his prior roles.

By 1996, the Company had doubled its production of caps and penetrated the environmental testing market with its 11mm lined caps. ILT began to differentiate itself by investing in vertically integrated manufacturing capabilities to support custom product development for its customers. The Company invested in building proprietary tooling, designing unique machinery, and training its technical staff.

In 2022 Kevin Frake was appointed as President of ILT.