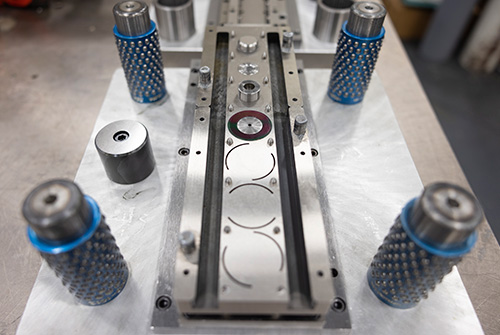

The state of the art equipment, owned and made by ILT at this facility, ensures that scheduled maintenance does not put equipment out of service for months at a time. Having a fully equipped tool shop, 3-D design capabilities and a team of exceptionally skilled engineers, ILT can produce automated equipment without 3rd party involvement. Investment into manufacturing equipment has allowed ILT the ability to produce product efficiently with consistency in quality.

ILT Manufacturing

Molding

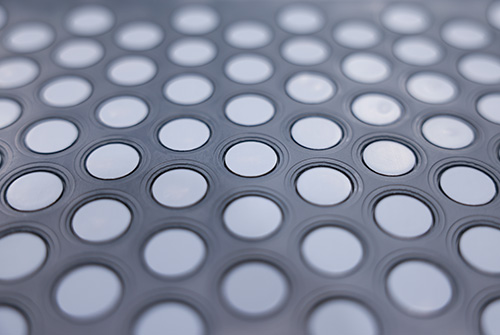

The ILT molding operation located at the Rensselear, NY facility, allows for all molded septa to be manufactured in-house. Utilizing Butyl and Silicone materials we offer a full range of product including Pharmafix and PFAS 11mm caps.

Unique equipment design allows for a complete PTFE film on molded septa

Polypropylene caps are molded using ILT owned tools which provides a consistent supply chain for the production facility

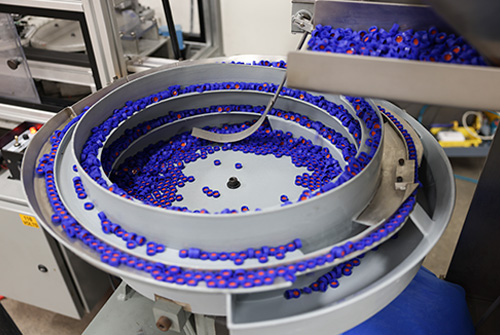

Investment in automation at ILT has been a constant since inception of the company. Today we operate on fully automated cap lining machines that have all components to manufacture a finished article using an all- in-one in-line process. ILT Inter Seal Bonding the liner into caps and, if required, slitting is performed as one continual operation. Vision camera systems are in place for full quality control.

Custom material can be designed & created based on the requirement of our customers

3-D design and printing provides ILT with equipment manufacturing that extends the customer experience

Testing new material in the ILT laboratory offers our customers unique customization opportunities working with compounds of choice.

Why Are Our Products Better?

Every ILT product has a detailed material specification aligned to it, which would include a drawing.

Drawings are created customer specific and protected for copyright.

All orders follow a manufacturing process as written according to the GMP of ISO 15378