Integrated Liner Technologies is

ISO 9001 15378 certified

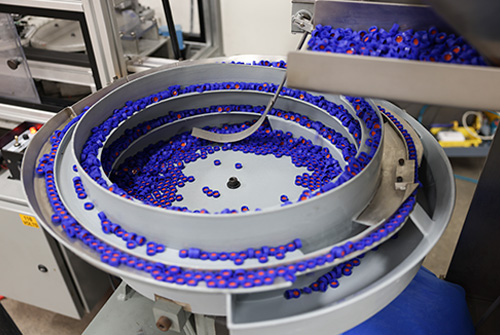

With over 30 years’ experience and highly qualified technical staff, ILT can offer customers the advice and problem resolutions needed for all your cap requirements. ILT is dedicated to manufacturing the highest quality liner materials and assembled caps for multiple industries.

Our knowledge of manufacturing silicone and fluoropolymers is extensive and as a US based self-manufacturing company, we provide a complete service from our NY state facility.

The Quality Management team investment is an invaluable resource to set and maintain the highest level of incoming raw materials through all steps of manufacturing ensuring product meets all written specifications. ILT continuous improvement program has raised the bar for manufacturing silicone septa providing customers with exceptional materials exceeding all regulatory requirements.