Solid phase microextraction (SPME) is widely used in analytical laboratories as a solvent free, efficient, and sensitive approach to sample preparation. Unlike traditional liquid extraction methods, SPME uses a fiber coated with a sorbent material to extract target analytes directly from a sample or its headspace. Because the fiber itself is both delicate and central to the method’s performance, the quality of supporting lab supplies such as caps, septa, vials, and liners plays a critical role in overall results. Choosing the right SPME products helps laboratories maintain stable conditions throughout sampling and injection while avoiding preventable damage to SPME fibers.

ILT SPME Products: Ready Liners and Assemblies

SPME and How It Works

SPME streamlines sample preparation by combining extraction and concentration into a single step. During analysis, the fiber is exposed to the sample matrix or headspace, where analytes are absorbed onto the coating before being introduced directly into an analytical instrument such as a gas chromatograph. This approach minimizes solvent use, reduces handling steps, and lowers the risk of external contamination. Compared with conventional liquid extraction techniques, SPME simplifies workflows while maintaining the sensitivity required for volatile and semi volatile compound analysis.

Industries That Rely on SPME

SPME is used across a broad range of industries that require reliable trace level analysis. Environmental laboratories apply it to air, water, and soil monitoring, while food and beverage labs use SPME to evaluate flavor compounds and detect contaminants. Agricultural testing includes pesticide and residue analysis, and pharmaceutical and biotech laboratories rely on SPME for drug development and quality control. Petrochemical, flavor, fragrance, and forensic laboratories also depend on SPME to analyze volatile compounds in complex matrices. As laboratories continue to prioritize green sample preparation methods, SPME remains a practical choice due to its minimal solvent requirements and reduced chemical waste.

Core SPME Supplies Labs Depend On

Successful SPME analysis depends on more than the fiber alone. Each supporting component plays a specific functional role in the process. SMPE vials provide a stable, enclosed environment for the sample and help establish consistent headspace conditions. Caps and septa allow repeated fiber insertions while maintaining a secure seal throughout sampling and injection. Inlet liners guide the fiber during injection and help ensure proper positioning and thermal behavior inside the inlet. When these components are properly matched to the method, laboratories can run SPME analyses with fewer interruptions and more predictable performance.

Why ILT’s SPME MicroCenter Caps and Liners Perform Better

ILT’s SPME MicroCenter caps and liners are engineered to address one of the most common failure points in SPME workflows: damage to the SPME needle fiber. ILT liners are designed to allow smooth, controlled penetration without bending or breaking the fiber. A standard outer liner thickness paired with a micro thin center provides easy entry while maintaining the structural support needed for repeated use.

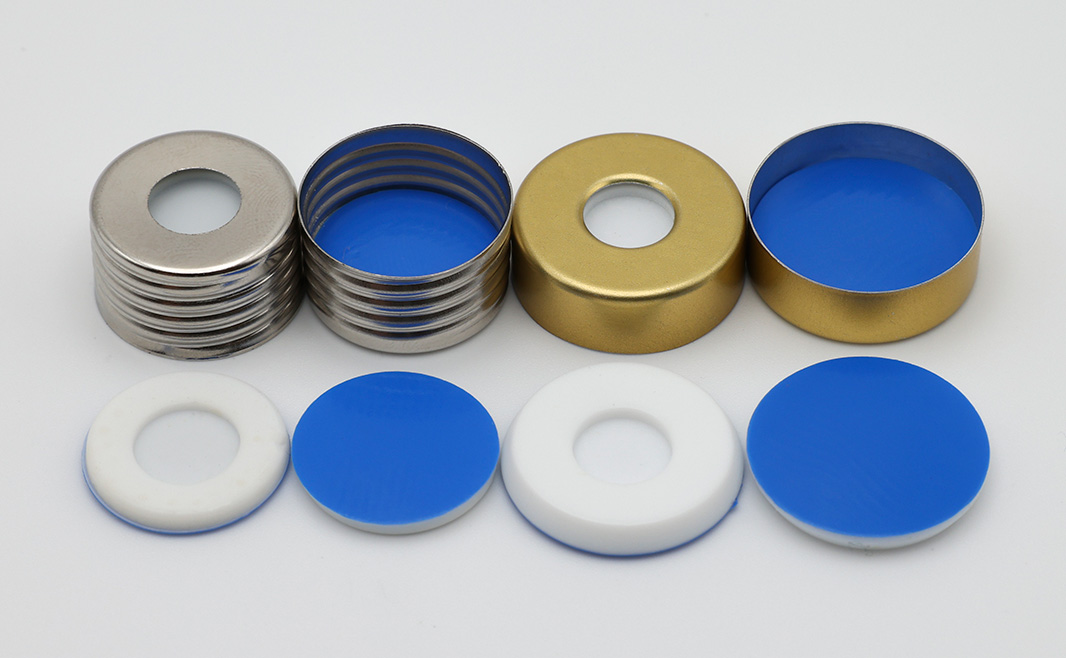

ILT septa feature a micro thin center that is easy to pierce and seals tightly after multiple punctures. Molded for dimensional conformity and manufactured from low extractable silicone, these septa support clean resealing and consistent performance across runs. ILT offers both 18mm screw caps and 20mm crimp caps to accommodate common SPME configurations and automated systems. Together, ILT’s caps, septa, and liners are built for durability, precise fit, and dependable operation in routine and high throughput environments.

Applications and Workflow Advantages

ILT SPME supplies improve laboratory workflows by:

- Reducing failures from poor sealing or fiber misalignment

- Ensuring smooth, reliable day-to-day operations

- Minimizing reruns and manual intervention

- Supporting standard instruments and automation

- Maintaining consistency and uptime in high-throughput workflows

Choosing the Right SPME Products

Selecting SPME consumables should be guided by the method, sample type, and frequency of use. Laboratories moving from liquid extraction to SPME often benefit from components that simplify fiber handling and maintain stable conditions during headspace sampling. Paying close attention to liner design, septa construction, and cap compatibility helps reduce avoidable errors and protects valuable fibers over time. Choosing well engineered components upfront can prevent downstream issues that compromise efficiency or data quality.

For laboratories seeking high-performance SPME products and solutions, ILT is a trusted source for caps, liners, and assembled crimps that support consistent workflows and long term use. Made in the USA, ILT products are recognized as some of the best SPME caps and liners available for protecting fibers and maintaining reliable analytical performance across a wide range of applications. Explore ILT’s full product line here.