All ILT PTFE-lined components are manufactured in the United States and shipped globally. This U.S.-based production allows ILT to maintain full traceability, consistent quality, and faster response times for customers worldwide.

5 Advantages of ILT PTFE Products

1. Enhanced Sample Integrity

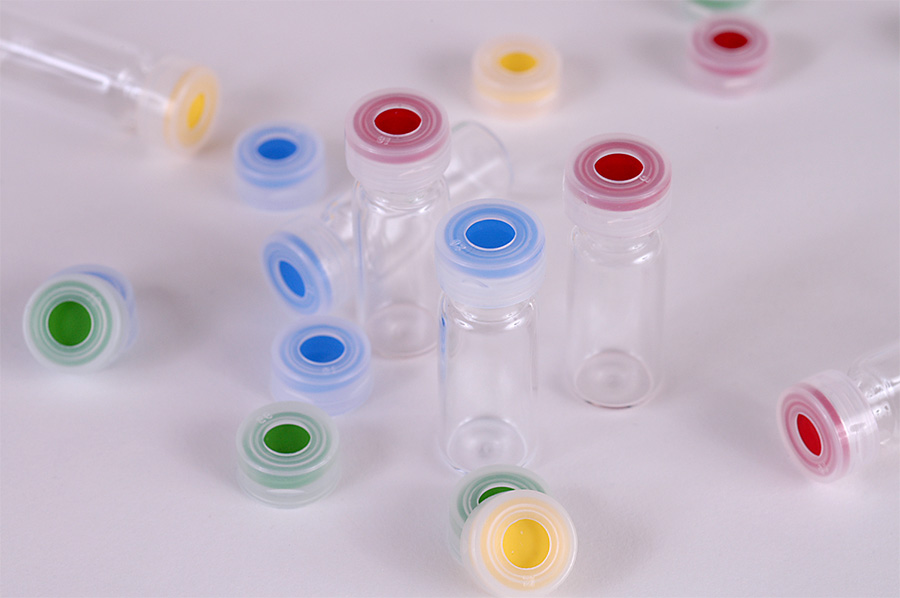

ILT’s silicone/PTFE liners act as a stable, inert barrier between the sample and the vial cap or septa material. This minimizes contamination risk and prevents unwanted chemical interaction, maintaining sample integrity and accuracy of every sample throughout handling and storage.

2. Reduced Analytical Errors

PTFE’s naturally non-stick properties help prevent sample adhesion, carryover, and residue buildup. For chromatography, headspace, and diagnostic workflows, this translates into cleaner results, reduced sample loss, and improved repeatability, qualities that laboratory professionals depend on.

3. Minimized Septa Coring

Septa coring occurs when a needle puncture removes small fragments of septa material, potentially contaminating samples or instruments. ILT’s silicone/PTFE-lined septa prevent this by reinforcing the puncture surface. The liner provides a smooth, resilient barrier that resists tearing and debris formation, keeping workflows clean and uninterrupted.

4. Uniformity Across Production

ILT’s precision manufacturing standards guarantee consistent PTFE thickness, surface smoothness, and adhesion from batch to batch. That uniformity translates into dependable septa and vial cap performance, reducing variability in analytical testing environments.

5. Molecular-Level Bonding

ILT’s PTFE liners are bonded using a specialized process that creates a durable molecular bond between PTFE and the base material. This method preserves the inherent flexibility of PTFE while preventing delamination, even under exposure to aggressive chemicals or repeated puncture cycles.