The science behind the scent industry.

Ensuring Quality with Fragrance Analysis

Fragrance analysis is the process of breaking down and examining the components of a fragrance.

- Chemical composition

- Aromatic ingredients

- Scent profile

- Biological and Environmental Interactions

Quality control is a critical process in the perfume and scented product industry.

Fragrance stability testing is crucial for assessing scent quality over time. Factors like light, temperature, and packaging can impact fragrance integrity. Testing methods include accelerated aging and light exposure. Tools like climate chambers and UV cabinets are used to simulate conditions and ensure consistent fragrance quality throughout its shelf life.

Fragrance composition involves blending aromatic ingredients to create scents, influencing fragrance character and performance. Understanding this composition aids in replicating, modifying, or enhancing fragrances, crucial for quality control and product development. Fragrance analysis deconstructs scents to identify components, crucial for replicating scents and ensuring regulatory compliance.

ILT’s UM4™ Ultra Mass Spec Caps

The fragrance industry demands extremely clean consumables. Volatile aromatic compounds are easily masked by background noise, bleed, or extractables from caps and liners. UM4™ Ultra Mass Spec Caps are designed to eliminate those variables.

ILT’s UM4™ caps are manufactured using high-quality silicone and PTFE, with liner materials conditioned to ILT’s Level-4 standard for ultra-low bleed performance. Each cap is tested and certified using GCFID, GCMS, and LCMS methods to ensure consistent cleanliness and performance in mass spectrometry workflows.

Advancements in technology have allowed for more precise identification and quantification of fragrance components.

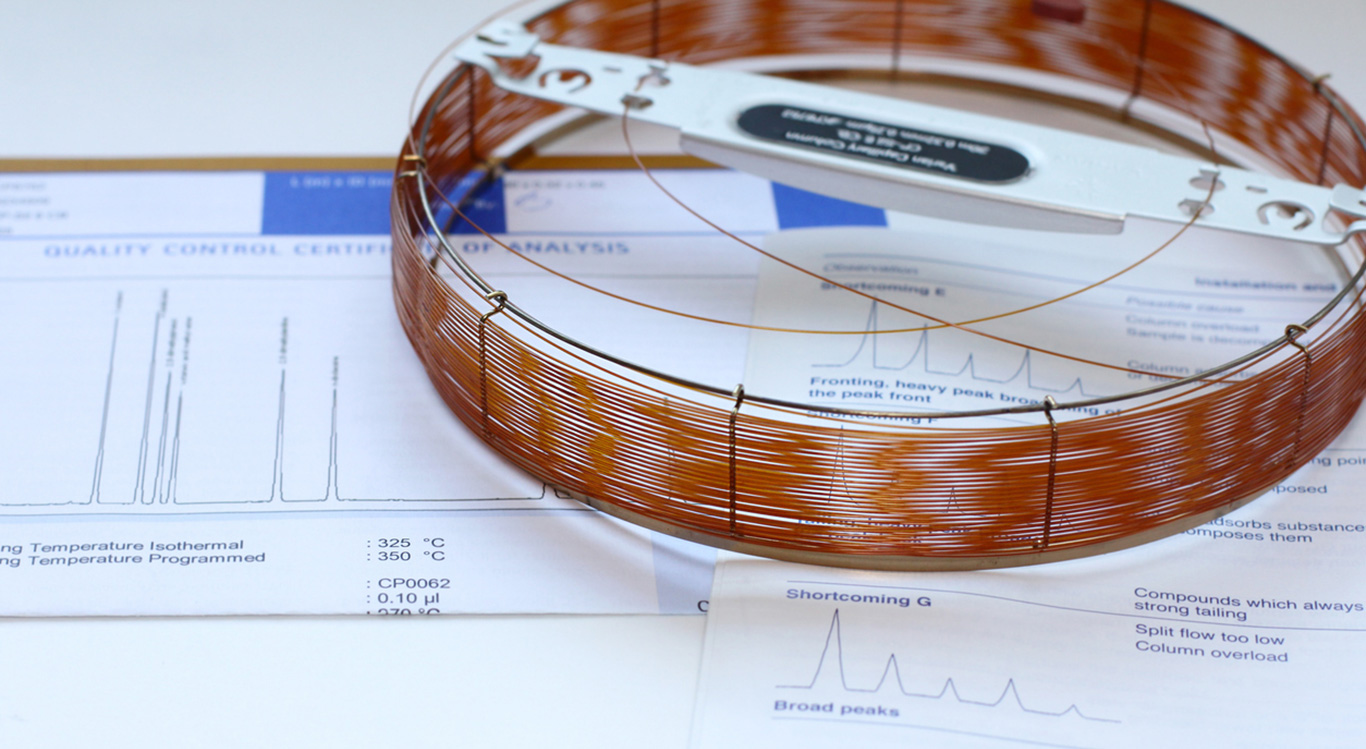

- Gas Chromatography (GC): Separates and analyzes volatile compounds in a fragrance sample.

- Mass Spectrometry (MS): Identifies individual compounds based on their mass and chemical structure.

- Chromatography-Mass Spectrometry (GC-MS): Combines GC and MS for comprehensive compound analysis.

- High-Performance Liquid Chromatography (HPLC): Analyzes non-volatile compounds in fragrances.

- Nuclear Magnetic Resonance (NMR) Spectroscopy: Analyzes the structure and composition of fragrance compounds.

- Fourier Transform Infrared Spectroscopy (FTIR): Identifies functional groups in fragrance molecules.

Headspace analysis is a technique used to capture and analyze the volatile compounds that are released from a fragrant product into the air.

This method is crucial in the fragrance industry, especially for studying scents as perceived by consumers without altering the sample. In fragrance development, this technique helps identify which components are most perceptible to the human nose. It is also invaluable for quality control, ensuring that the intended aroma profile of a product is consistently achieved. Headspace analysis is essential for replicating natural scents accurately in a laboratory setting, enhancing the overall fragrance creation process.

During manufacturing, fragrances are systematically tested to confirm that the scent remains true to its intended profile.

Tests are also performed to check for the presence of any harmful or allergenic substances, confirming that the product is safe for consumer use. This is particularly important as fragrances directly interact with the skin and can have significant sensory impacts. Maintaining strict quality control helps a brand uphold its reputation, as consistent and safe products are crucial for customer satisfaction and loyalty. Adherence to regulatory standards is another key aspect, as the fragrance industry is subject to various national and international regulations regarding ingredients and their concentrations.

Frequently Asked Questions

Fragrances are exposed to different environmental factors such as heat, light, and air, then assessed for any changes in aroma, color, and overall composition. Stability testing also aids in predicting the shelf life of the fragrance and maintains its consistency and effectiveness throughout its intended usage period.

Most fragrances typically consist of top, middle, and base notes. Top notes are the initial, light scents perceived, middle notes form the heart of the fragrance, and base notes are the deeper, long-lasting aromas. Balancing these notes is crucial to crafting a harmonious and appealing fragrance. The process requires a deep understanding of how different scents interact and evolve over time on the skin and in the air.

Fragrance laboratories commonly rely on consumables such as autosampler vials, screw caps, and septa. These supplies must minimize bleed, extractables, and contamination to preserve volatile aromatic compounds and maintain accurate results. High-purity caps and liners are especially important for trace-level analysis, quality control, and regulatory testing where consistency and data integrity are critical.